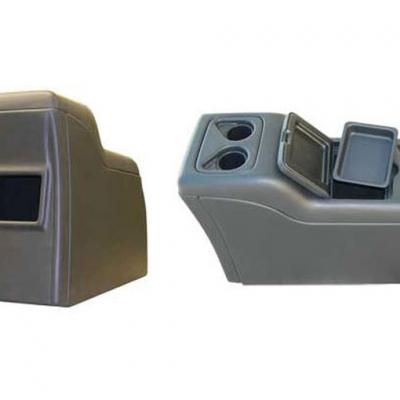

Thermoforming is a plastic manufacturing process that offers many benefits for businesses, including cost-effectiveness, design flexibility, and durability. Choosing the right thermoforming partner is essential for ensuring that your parts are of high quality, delivered on time, and meet your specific design requirements. In this article, we'll explore how to choose the right thermoforming partner for your business.

Experience and Expertise

One of the most important factors to consider when choosing a thermoforming partner is their experience and expertise. Look for a company that has a proven track record of producing high-quality parts and that has experience in your specific industry. Additionally, look for a company that has a team of experienced engineers and technicians who can provide guidance and support throughout the manufacturing process.

Quality Control

Quality control is another essential factor to consider when choosing a thermoforming partner. Look for a company that has robust quality control processes in place, including regular inspections and testing. Additionally, look for a company that has certifications, such as ISO 9001, which indicate a commitment to quality and customer satisfaction.

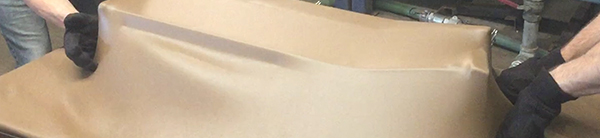

Equipment and Capabilities

The equipment and capabilities of a thermoforming partner are also important factors to consider. Look for a company that has state-of-the-art equipment and a wide range of capabilities, including the ability to work with a variety of materials and part sizes. Additionally, look for a company that has the capacity to meet your production needs, both in terms of volume and timeline.

Customer Service

Choosing a thermoforming partner that provides excellent customer service is also important. Look for a company that is responsive, transparent, and communicative throughout the manufacturing process. A good thermoforming partner should be willing to work with you to understand your specific needs and to provide solutions that meet those needs.

Cost

While cost should not be the only factor considered when choosing a thermoforming partner, it is an important one. Look for a company that offers competitive pricing without compromising on quality or service. Additionally, consider the total cost of ownership, including any maintenance or repair costs associated with the parts produced.

Conclusion

Choosing the right thermoforming partner is essential for ensuring that your parts are of high quality, delivered on time, and meet your specific design requirements. When evaluating potential partners, consider their experience and expertise, quality control processes, equipment and capabilities, customer service, and cost. By choosing the right partner, you can ensure that your thermoformed parts meet your specific needs and contribute to the success of your business.