In the highly competitive retail industry, custom displays can be a powerful tool for attracting customers and boosting sales. Thermoforming, a plastic manufacturing process that involves heating a plastic sheet and forming it into a specific shape using a mold, is an ideal method for creating custom retail displays. In this article, we'll explore how thermoforming can be used to create custom retail displays that are both eye-catching and functional.

Customization

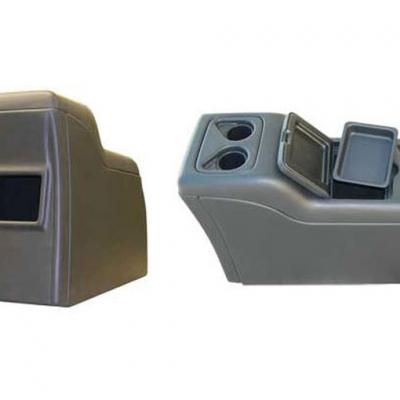

One of the main benefits of thermoforming for retail displays is its customization capabilities. Thermoforming allows for the creation of custom displays that are tailored to the specific needs of a business, including size, shape, and color. Custom displays can be designed to fit the specific product, brand, and messaging needs of a business, creating a more effective and memorable display.

Durability

Thermoformed retail displays are also highly durable, making them a cost-effective choice for businesses. Thermoformed plastic is able to withstand impact, making it resistant to damage and wear-and-tear. This means that thermoformed retail displays are more likely to have a longer lifespan, reducing the need for frequent replacement and saving businesses money in the long run.

Versatility

Thermoforming is a highly versatile process that can be used to create a wide range of retail displays, from simple signage to complex point-of-sale displays. Thermoformed displays can be designed to fit any size, shape, or product type, making it a flexible solution for businesses of all sizes and types.

Ease of Assembly

Thermoformed retail displays are also easy to assemble, making them an efficient option for businesses. Thermoformed displays can be designed to include snap-together components or to be self-supporting, making assembly and disassembly simple and quick. This allows businesses to set up and take down displays quickly and efficiently, reducing downtime and improving the overall customer experience.

Cost-Effective

Thermoformed retail displays are also a cost-effective option for businesses. Thermoforming molds are typically less expensive to produce than injection molds, making it a more affordable option for custom displays. Additionally, the thermoforming process is generally faster and more efficient than other methods, allowing for larger production runs at a lower cost per part.

Conclusion

Thermoforming is a highly effective method for creating custom retail displays that are both functional and eye-catching. With its customization capabilities, durability, versatility, ease of assembly, and cost-effectiveness, thermoforming is an ideal solution for businesses looking to create impactful displays that attract customers and boost sales. If you're looking to create custom retail displays for your business, consider thermoforming as a cost-effective and efficient solution.