The Benefits of Rapid Prototyping Using Thermoforming Process

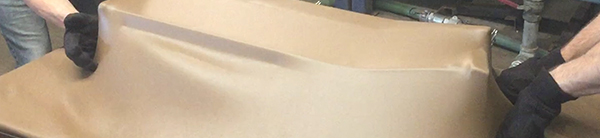

Rapid prototyping is an essential step in the product development process, allowing designers and engineers to quickly and efficiently test their designs before moving on to full-scale production. While there are many different rapid prototyping methods available, thermoforming is an increasingly popular option due to its speed, cost-effectiveness, and versatility. In this article, we'll explore the benefits of rapid prototyping using the thermoforming process.

Speed

One of the main benefits of rapid prototyping using thermoforming is its speed. Thermoforming molds can be produced quickly and at a relatively low cost compared to other prototyping methods, such as injection molding. This allows designers and engineers to quickly test and refine their designs, reducing the time to market for new products.

Cost-Effectiveness

Another benefit of rapid prototyping using thermoforming is its cost-effectiveness. Thermoforming is generally considered to be a more cost-effective option for prototyping than other methods, as thermoforming molds are typically less expensive to produce than injection molds. Additionally, thermoforming can be used with a wide range of materials, including recycled materials, further reducing the cost of prototyping.

Versatility

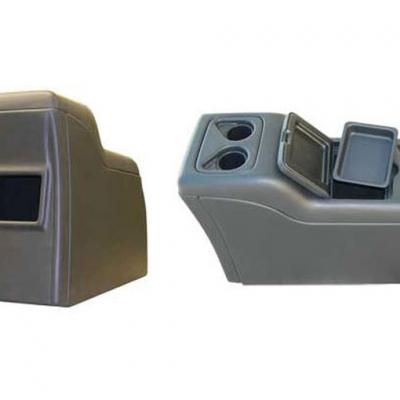

Thermoforming is a highly versatile process that can be used to produce a wide range of prototypes, from simple trays to complex automotive components. This versatility allows designers and engineers to test their designs in a variety of applications and to make any necessary adjustments before moving on to full-scale production.

Ease of Use

Thermoforming is also an easy process to learn and use, even for those without a background in manufacturing or engineering. With the right equipment and training, anyone can produce high-quality thermoformed prototypes quickly and efficiently.

Customization

Thermoforming allows for easy customization of prototypes. With thermoforming, designers and engineers can quickly and easily modify the shape, size, and thickness of a part to meet their specific design requirements. This flexibility allows for more thorough testing of designs and can lead to better final products.

Conclusion

Rapid prototyping using the thermoforming process offers many benefits for designers and engineers, including speed, cost-effectiveness, versatility, ease of use, and customization. By using thermoforming for rapid prototyping, companies can reduce the time to market for new products, save on prototyping costs, and improve the quality of their final products. If you're looking for a cost-effective and versatile option for your rapid prototyping needs, consider thermoforming.